For medical device manufacturers that sell and service complex equipment, it has historically been challenging to get an accurate account of where all field device assets are currently located.

In this post, we’ll look at how a connected field service app, along with QR (Quick Response) code scanning capability, addresses this challenge and makes the entire field service operation more efficient.

The traditional tracking problem stems from a lack of end-to-end tracking of the continual movement of device assets from:

- A production facility to a warehouse

- A warehouse to a customer location

- A warehouse to a field service engineer’s trunk stock

- Customer locations to an FSE’s trunk stock (obsolete assets)

- An FSE’s trunk stock to a warehouse or repair facility

- One FSE’s trunk stock to another FSE’s trunk stock

When assets are not properly tracked in the field, there are two major problems:

1. It’s more difficult to properly service end-customers

2. Expensive components can go missing—with no way to track at what point they were misplaced, lost, or stolen.

Technology Enablement of Improved Asset Tracking

Fortunately, the convergence of several technology factors has made field asset tracking easier and has made field service more efficient. These factors are:

- More intelligence built into complex medical devices

- The ability for a mobile device camera to function as an app’s QR code scanner

- Better usability of enterprise apps on iOS and Android devices

- Faster and cheaper design and deployment of enterprise apps on mobile devices

- A direct connection from mobile devices to enterprise CRMs like Salesforce

- Easier integration between CRMs like Salesforce and ERP systems

The unifying human factor is a team of creative consultants and integrators who can understand a device manufacturer’s business requirements, develop processes and tie all the technology components together.

Before we get to the cost-saving asset tracking part, let’s first look at the big picture of how Salesforce Field Service works.

The Salesforce Field Service Platform

Salesforce Field Service has a foundational database structure and set of functionality for managing field service flows.

Based on customer requirements, custom database objects (such as Trunk Stock) can be added to the foundation. Tools within Salesforce (e.g., Flow Builder) and validation rules can be configured to support business processes.

Field Service Dispatching

The dispatching of field service engineers or technicians to install, repair, and de-install medical devices can be done by different types of Salesforce users. It can be done by the FSEs themselves and/or by dispatchers.

When a Work Order is created for a customer, a Service Appointment record can be added to the Work Order. The Service Appointment record includes fields for Subject (“Install New Device”) Service Address, Scheduled Times, and Actual Times.

The FSE Mobile Device App

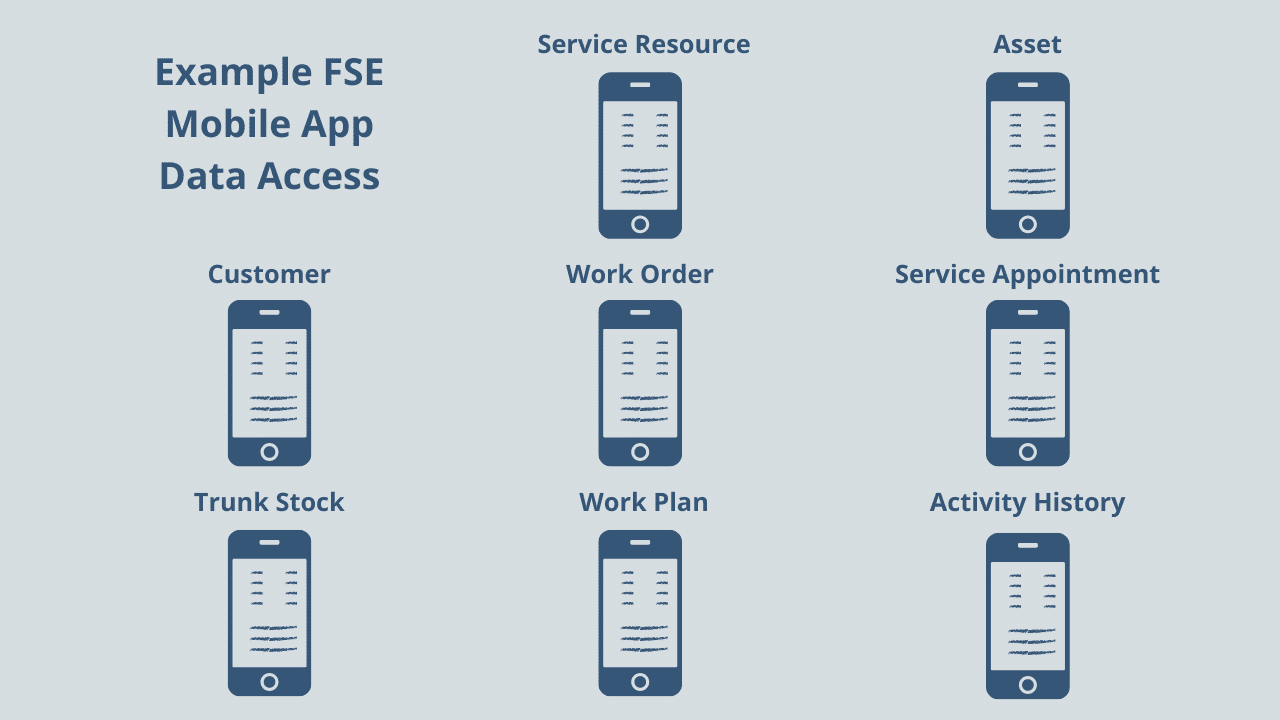

The field service mobile app gives the field engineer a view of Service Appointments, Work Orders, Work Plans, and more.

An example of a Work Plan could include the steps required to install a new device. An FSE can check off each step on their mobile device as they are completed. Then on the mobile app, an FSE can log the actual on-site start and end times—and finally mark the Service Appointment as “Complete.”

One of the Work Plan steps in a new installation is to scan the QR code that the device provides. Let’s take a look at how that works.

Device Self-Inventory and QR Code Generation

Medical device manufacturers have been building more intelligence into their devices.

Some medical devices can self-inventory and then generate a report on all of their current internal assets in the form of an on-screen, dynamic QR code. The QR code is dynamic because any time an asset is added to or removed from a device, the QR Code will automatically update to reflect the change.

Most of us are familiar with simple QR codes that house only a web address. It’s common for restaurants to use these to direct patrons to a menu page. If you scan the following simple QR Code with your smartphone, you can open our homepage in your mobile browser with a single tap:

What’s known as a Model 2, Version 40 QR code is much larger than a code for a web address. The Version 40 code has a grid size of 177×177 [squares]. It can hold up to 4296 alphanumeric characters. In most cases, this is enough characters to hold all of a medical device’s current asset information.

As a simple example of a large QR code, the data in the following table are all contained within the QR Code you see below.

| Type | Name | Serial Number | Parent Asset | Position | Install Date | Status |

| Housing | HS100 | N6543897 | N/A | N/A | 12/01/21 | Active |

| Card Slot | CS8 | N987654320 | HS100 | 1 | 12/01/21 | Active |

| Card Slot | CS8 | N987654319 | HS100 | 2 | 12/01/21 | Active |

| Card | CD1 | N12345678 | CS8 – N987654320 | 1 | 12/01/21 | Inactive |

| Card | CD1 | N12345679 | CS8 – N987654320 | 2 | 12/01/21 | Active |

| Card | CD1 | N12345680 | CS8 – N987654320 | 3 | 12/01/21 | Active |

| Card | CD2 | N12345681 | CS8 – N987654319 | 1 | 12/01/21 | Active |

| Card | CD2 | N12345682 | CS8 – N987654319 | 2 | 12/01/21 | Active |

If you scan the above QR code with your smartphone, you will see the same information as in the table — but the list is in a raw data format.

By using the scanning function within a field service mobile app, an FSE can scan a QR code similar to this. The mobile app will then structure the raw data to make it readable on a mobile device screen.

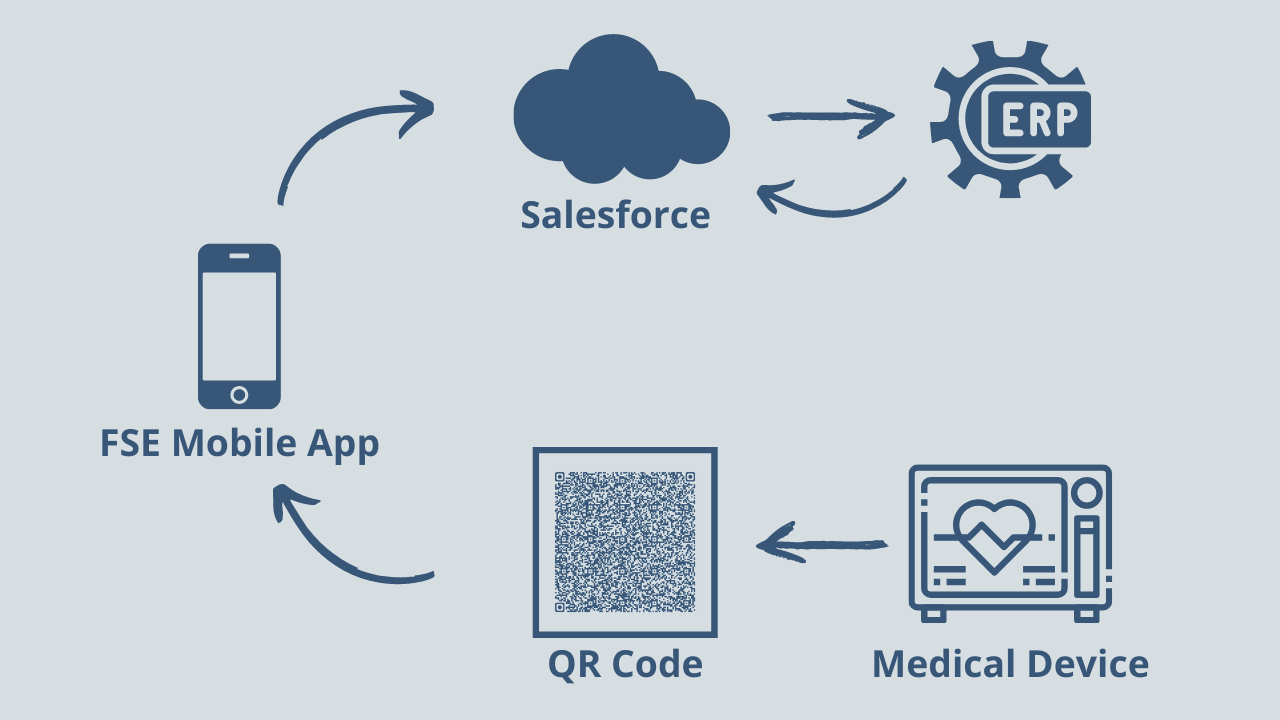

The device’s current asset information will immediately update the corresponding Salesforce Asset record. New Asset records can be added, and existing Asset records can be modified. Salesforce, in turn, updates the ERP system.

Here’s what the full device data collection and transfer flow look like.

In addition, there is an automatic transfer of FSE trunk stock to the device inventory in Salesforce.

Example Field Service App Use cases

Here are some of the use cases around the field service app and the QR code scanning functionality.

- New device installation

- Troubleshooting and replacement of defective assets

- Manual entry of assets

- New Work Plan creation while in the field

- Out of box failure

- Device de-installation (render all assets inactive)

When asset tracking is fully integrated with a field service engineer’s Work Orders and Work Plans, field asset accounting improves while financial losses decrease.

Salesforce Field Service, along with a configured mobile app for FSEs, makes field asset tracking easier and makes field service more efficient.

To learn more, please get in touch with us.